------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

We understand the pressure you are under to cut your organization’s carbon footprint – and the corresponding taxes! New carbon taxes and stricter regulations just intensify this pressure. But as you explore all your options to go green, you may be overlooking the easiest, most cost-effective way to dramatically reduce carbon emissions across your entire operation...

Upgrade the intake filters on your gas turbines

When you use more efficient air intake filters that are adapted to your environmental and operational conditions, you get cleaner-running engines with less fouling, corrosion and reduced air resistance across the system. The engines don’t have to work as hard, so they use less fuel. Burning less fuel for the same output means less CO2 produced, stopping CO2 before it’s even released. Depending on your environment, operations, and current solution

– you could slash your total CO2 emissions by more than 5% per year, per megawatt hour produced..

Upgrading from a standard filtration solution to an optimized high-efficiency EPA solution may cut your CO2 output by thousands of tonnes per turbine each year. Multiply that saving across your entire fleet to see the true impact of this painless, common-sense retrofit.

So when it comes to slashing your carbon footprint, remember these three words…

BOOST TO REDUCE!

It’s the best idea you’ve never thought of to drastically reduce your CO2 emissions.

| Air inlet filters |

Impact on heat rate |

Emissions related to filtration |

Yearly conclusions |

|||

|---|---|---|---|---|---|---|

| Prefilter | Final filter | Heat rate reduction vs. baseline (kJ/kWh) |

Tonnes of CO2 per year |

Total CO2 reduction vs. baseline (%) |

Total CO2 reduction vs. baseline (%) |

Equivalent cars removed from the road |

| Bag filter G4 | Bag filter T6 | 0 | 38 000 | |||

| 30/30 GT T3 | Composite T8 | 180 | 24 000 | 14 000 | 2.0% | 8 000 |

| 30/30 GT T3 | Composite T9 | 270 | 17 000 | 21 000 | 3.0% | 12 000 |

| Cam-Flo Hybrid T7 | CamGT 3V-600 T10 | 395 | 7 000 | 31 000 | 4.5% | 17 000 |

| CamGT 3V-600 T8 | CamGT 3V-600 T12 | 440 | 3 000 | 35 000 | 5.0% | 18 000 |

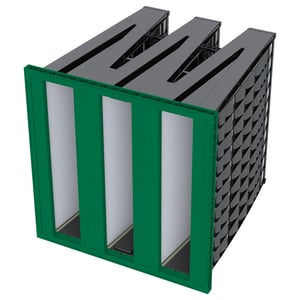

Gas turbine EPA filters are available in the following models.