The food and beverage industry is affected by unique air quality challenges that can risk the health and safety of workers, production equipment along with a potential for contamination. Let’s look at how high-efficiency air filters can provide an effective and affordable solution.

Across the world, the daily challenges facing the food & beverage industry have been intensifying for some time. From product safety recalls to fluctuations in global food prices, food manufacturers and packaging plants seemingly have enough on their plate when it comes to product safety.

Like any other commercial operation, the presence of airborne pathogens, mold spores, and volatile organic compounds (VOCs) can threaten food safety and quality. Commercial operators like food producers, dairy processors, and beverage manufacturers must pay very close attention to how effective their air filters are and how effective they are at protecting the people, process, and the environment the filters serve. For most, upgrading to high-efficiency air filters is an effective way to reduce the threats from contaminants while improving facility airflow and lowering maintenance costs.

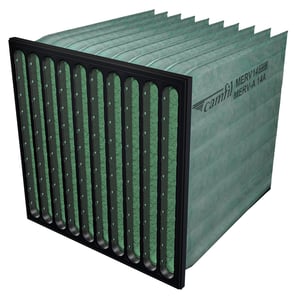

The first step is to determine what level of filtration is needed in a given area. This can vary widely depending on the type of product you are manufacturing and its processes. Areas considered low care or low risk will often have different requirements than those considered high care or high hygiene. These areas often require multiple stages of filtration, with final filters in the MERV 14/14A to MERV 16/16A range, depending on the application. Sufficient airflow is also required in order to maintain positive pressure zones in higher risk areas.

The below diagrams will explain how food is segmented based on its characteristics and how air quality or air care is determined.

HVAC systems in the existing facilities may not be designed to achieve increased levels of air changes as well as improved filter efficiency. When these improvements are not available for upgrading the system, the process becomes more challenging due to the cost and expenses. This challenge can be easily met by Camfil's Air Purifiers/Air Cleaners. Camfil recommends using a mobile HEPA air cleaner or air purifier to supplement the existing HVAC system to achieve the required air changes to support the food production facility.

Camfil offers the food & beverage industry a complete range of air filters – specially designed for use in processes with strict requirements for safety, traceability, and control.