Achieve hygienic air quality and reduce the potential for contamination in the dairy production process with complete air quality solutions from Camfil.

Protect your high-risk dairy process from impurities – and extend product shelf life – with pure, filtered air in your processing areas. Camfil’s energy-efficient filters, rigorously tested and certified to standards and designed for food applications, help manufacturers around the world reduce the risk of contamination and meet strict regulatory requirements.

Regardless of the type of dairy product, dairy processes involve receiving raw milk and then transforming it into finished products. Airborne impurities like yeast and mold fungi greatly impact the shelf life of dairy products like milk and milk powders, cheese, yogurt, ice cream and butter. Infant formulas are even more sensitive to process quality as the stake is infant life.

But eliminating airborne contaminants is no easy task because of their size – on average, about 0.6 microns.Even with clean processing equipment, unsecured gaps can allow microbe-filled impure air to come into contact with the products. Therefore, any process-related components must comply with food safety as well as sustain cleaning procedures.

It’s no wonder that dairy foods must meet stringent regulations and requirements for food production safety. Controlling air quality and air change rates, together with temperature and humidity levels, in cleanrooms and filling halls all play a key role in contamination control.

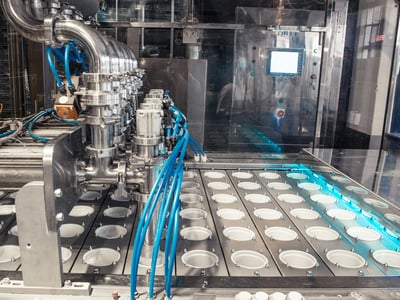

In this industry, you simply can’t skimp on quality. Fluid bed dryers, aseptic filling lines, slicing, maturing and packaging lines must be equipped with filters of the highest quality and most efficient filtration levels to ensure that food spoilage, recall and customer risk threats are completely removed.

What appears to be cost-saving equipment is risky. If that equipment has not been properly tested and certified to meet requirements, it could end up costing you much more in the long run.

Whatever the risk level you face in a specific application or processing/packaging area, Camfil offers a huge variety of pre-filters, fine filters, HEPA filters, ULPA filters, terminal housings and recirculating air cleaners to meet your needs.

Dust collectors safely handle exhaust air from food processing and packaging applications, therefore improving the IAQ, preventing cross-contamination and reducing the nuisance dust in the workplace.

In high-hygiene areas, products requiring the highest hygiene levels undergo final processing and packaging. Here, you need the highest air quality to effectively eliminate all contamination hazards. For dry dairy powder handling, aseptic filling, packaging and more.

Low-care areas include areas where production and product handling do not occur. Camfil recommends products that adhere to EN 16798 to best protect the health of your building occupants. For office spaces, main corridors, and reception areas.

High air quality is crucial for product quality and safety in food and beverage production. Camfil AHU products are designed to protect people, products and processes while also reducing energy costs.

In high-care areas, you need to protect equipment or minimize contamination before products enter a high-hygiene area. Here, you need high airflow and positive pressure environments. For ready-to-eat production, condensed dairy, cream, yogurt, frozen dessert processing and packaging, cheese processing, and drying halls.

Medium-care areas, where raw material is stored, need to be kept clean to protect against product contamination. These areas include milk receiving and storage, and raw ingredient handling.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Case studies Food and beverage Life science and healthcare

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

The food and beverage industry is affected by unique air quality challenges that can risk the health and safety of workers, production equipment along with a potential for contamination. Let’s look at how high-efficiency air filters can provide an effective and affordable solution.

Case Study: Dual 9 air filter. Higher performance, extended life (3-4 times longer), lower total cost and increased containment collection.

Some processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.