During the production of lithium-ion batteries, many different airborne contaminants are generated that can affect the health of workers. Ensuring that these airborne contaminants are removed and captured from your facility is critical to the safe operation of your production facility.

The most critical environmental item to be controlled in battery production facilities is relative humidity, sometimes as low as a dew point temperature of -94º Fahrenheit. In order to maintain this level, the rooms must be sealed to prevent the introduction of any moisture. For lithium-ion battery cells, clean materials account for 85% of the pack process materials cost. Reducing contamination through all stages of the manufacturing process will significantly increase the yield, which has been known to be 50% when contaminant levels are not controlled properly. Increased yield and better performing cells will foster the market’s acceptance of this new technology. Improving and maintaining air class inside the building will increase yield and produce better performing cells this will improve productivity and promote faster adaptation of this transport mode.

Different types of lithium-ion batteries use different chemistries and have different performance, cost, and safety characteristics. The cells of a lithium-ion battery contain separators that keep the anodes and cathodes, or positive and negative poles, from touching each other. If a piece of metal gets too close to the separator, it can puncture the separator and cause a short circuit. Controlling the air quality during the manufacturing process reduces this costly contamination, increases yield and assures that a quality product will make its way to the user. Camfil clean air solutions will protect your processes by reducing the airborne contaminants that foul or short circuit cells. Yield is increased and a quality product is packaged for the user

During the production of lithium-ion batteries, different particulates, gases and toxins are created that can cause a risk to both the people within your factory and external stakeholders. Ensuring that the health of all stakeholders is properly addressed will ensure a safe working environment. Camfil clean air solutions can help to capture and remove these potentially harmful contaminants in the air to ensure a safe and clean working environment.

Reducing energy costs and becoming “Net Carbon Zero” is a key initiative of many of the world's leading brands. Did you know that HVAC systems can equate to over 50% of your total energy consumption and of this 30% can be directly related to the air filter? Camfil clean air solutions are designed to ensure your plant is energy optimized without compromising on air quality.

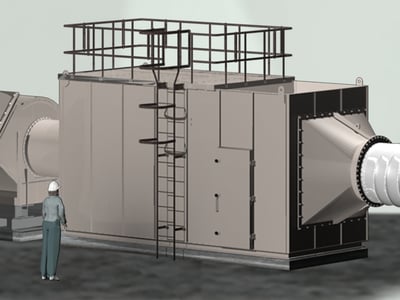

Battery cell production involves new manufacturing processes based on laser technology that generates dust & fumes that must be extracted in a controlled manner to eliminate the risk of contamination and harm to the personnel.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

Protect people, processes, products and equipment while lowering energy and maintenance cost with low pressure drop, long lasting air filters.

Controlled environments must protect critical processes and personnel. A high level of air cleanliness is essential to protect products and to contain hazardous compounds. High-quality filtration systems help ensure regulatory compliance and maintain efficient operations.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Take a Breath Case studies Food and beverage Life science and healthcare

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageIn the realm of controlled environments, where precision, purity, and protection are paramount, high-efficiency particulate air (HEPA) filters emerge as unsung heroes

Often the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

Processes in manufacturing facilities often generate dust and fumes which for example can pose health risks for your operators or compromise the quality and safety of your products. Determining the right capture and filtration solution helps to protect against the main risks of uncontrolled emissions and thus to create safe work environments.