Luchtfiltratie speelt een cruciale rol in veel vormen van energieopwekking zoals wind, thermisch, nucleair of biogas. Luchtfilters zijn cruciaal voor de veiligheid en de efficiëntie van het proces.

In zeer competitieve en gereguleerde markten kunnen innovatieve luchtfiltratieoplossingen een competitief voordeel bieden aangezien ze grote impact op de winstgevendheid van ondernemingen hebben. Een goed begrip van de lokale omstandigheden kan luchtinlaatsystemen optimaliseren om te voldoen aan uw operationele en onderhoudsbehoeften, en service internals en output te verhogen.

What are you looking for?

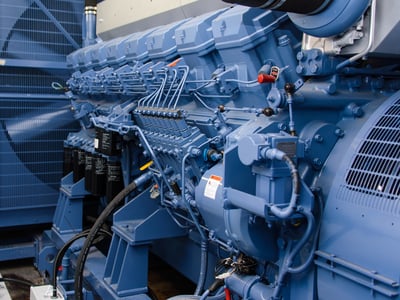

Diesel- en gasmotoren moeten beschermd worden tegen de elementen, extreme temperaturen en vervuiling tijdens het verbrandingsproces. De omgeving moet ook beschermd worden tegen de hete uitlaatgassen. Robuuste oplossingen beschermen tegen dergelijke risico’s.

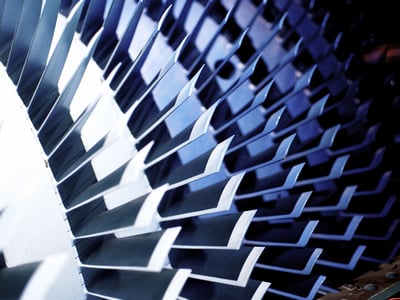

Gasturbines zijn zeer efficiënte, kwetsbare machines die kunnen worden gebruikt voor het opwekken van elektriciteit of als mechanische aandrijving voor diverse processen. Ze worden overal ter wereld gebruikt en de gebruiksomstandigheden kunnen drastisch variëren. Om passende bescherming te kunnen bieden moet de filteroplossing hierop worden aangepast.

Turbomachines en elektrisch materieel zoals generators dienen beschermd te worden tegen weersinvloeden en extreme temperaturen door middel van geschikte koelende ventilatie. Het beschermingsniveau van de ventilator moet worden aangepast op de omgeving om bescherming te bieden tegen water, zout en andere vervuilende stoffen.

Luchtcompressoren zijn een cruciale factor voor veel procesindustrieën die efficiënte filtratie behoeven om voor langere periodes operationeel te blijven, zonder onderbrekingen. Omgevings- en gebruiksomstandigheden kunnen drastisch variëren. De vereiste filteroplossing moet daarom worden aangepast op de lokale omstandigheden van uw onderneming.

Camfil levert al sinds het begin van de jaren ’60 oplossingen aan de kernenergiesector. Met ervaring opgedaan op meer dan 90 centrales wereldwijd, zijn we momenteel wereldleider op het gebied van radioactieve deeltjes en gasfase filtratie.

Windturbines functioneren onder zeer zware omstandigheden. Luchtinlaatfilters moeten zeer efficiënt en robuust zijn om er voor te zorgen dat ze lang mee gaan en weinig energie verbruiken.

Wist je dat Camfil een volledig assortiment retrofit filters heeft die kunnen worden gebruikt in alle meest voorkomende merken op de markt. Camfil filters zijn niet alleen ontworpen om te werken, maar ook om de prestaties van uw stofafzuigsysteem te optimaliseren.

Food and beverage Life science & gezondheidszorg Energie & Power Systems Productie & machinebouwCCC Pesquería in Mexico heeft een upgrade naar TurboPulse T10 filters uitgevoerd, waardoor de stroomdegradatie 5x is verminderd, de jaarlijkse productie met ~20.000 MWh is toegenomen, er jaarlijks $600.000+ winst is gemaakt en hun ecologische voetafdruk is verkleind.

Energie & Power Systems Case studiesEen toonaangevende staalproducent verbeterde de filtering van de blower, waardoor de levensduur van het eindfilter met 16x werd verlengd, de levensduur van het voorfilter met 4x en een operationele beschikbaarheid van 100% werd bereikt.

Camfil designs a static EPA retrofit gas turbine filtration solution for LM6000 turbines to ensure they deliver reliable power & heating to the district. The result of the upgrade was 3x more filter life, reduction in CO2 emissions by 1 100 tons per year, and fuel consumption savings of 650 000 Sm3 per year.

The wastewater undergoes a long process at Middelfart Wastewater, where the wastewater is treated and at the end of the process it eventually becomes purified water which is then released to the sea surrounding Middelfart. In addition, the byproducts biogas is converted to electricity and heat as well as bio-fertilizer that is being used on farmers’ fields.

Dyna Mig had a competitor dust collector solution that regularly caused costly downtime. With the help of Camfil’s expertise and a flagship Camfil Gold Series GSX dust collector system, Dyna Mig was able to eliminate all unscheduled downtime and cut their heating costs to a minimum – as well as work safer.

Camfil Power Systems (PS) provides filtration and acoustical solutions for turbomachinery including gas turbines, generators,industrial air compressors and diesel engines. Turbomachinery technology has evolved tremendously over the past decades.

ISO 29461-1 is the first international test standard for reporting the efficiency for the entire range of air intake filters for gas turbines, compressors, and other turbomachinery applications.

The biogas process is critical as it releases heavily contaminated gasses that can cause engine corrosion and equipment abrasion, causing unscheduled downtime for maintenance and repair, which results in loss of output and profit. Luckily, there are several ways of solving molecular filtration in biogas plants with different types of filter media in deep beds.

The CamClose panel air filter is engineered for gas turbine air intake systems to provide hassle free operations, stable performance and increased protection.

CamPure 32 is the new ideal Camfil media for the removal of hydrogen sulfide during the production of biogas in an anaerobic process. Learn how this farm in France applied the high quality chemical absorbent media to their biogas application.

Tata Power Ltd, India's largest integrated power company requests Camfil for a Cam-Flo pocket bag filter and CamGT static air filter retrofit after heavy hot corrosion in the gas turbine and high pressure drop jeopardized performance and safety.

Case Study: The BioGas produced is heavily laden with H2S (hydrogen sulphide), a gas that can cause corrosion and pitting inside the gas engine. A solution was required where a high level of abatement of H2S was possible and an easy filter media maintenance.

Dalkia, a leader in the French gas turbine market, launched a national comparative test for various air intake filters, including Camfil's Hi-Flo pre-filters and CamGT EPA filters, to increase power production for their 10 GE LM6000 gas turbines.

Case Study: Clean Air For Cofely United Kingdom. Cofely, a GDF Suez company, is one of the leading experts in energy, technology and facilities management services with business outsourcing. Camfil provides City air purifiers to improve IAQ.

Noise complaints from neighboring communities in Thailand prompted the plants to evaluate a noise-reducing filtration system. The CamGT high efficiency air filter solution not only improved the noise levels, it also increased turbine availability, improved pressure drop and helped the gas turbine produce more power.

Located offshore Ivory Coast, Africa, the CamGT EPA filter solution saves Foxtrot International 3 shutdowns per year and eliminates salt corrrosion, without compromising on footprint.

Gas Turbine Application: Do you operate in a coastal or offshore site? Unfortunately, you probably have to deal with corrosion related issues. You can, however, operate corrosion-free if you take the right measures.

Turbomachinery: Air inlet filtration systems should be designed to suit the environment. Because of market pressures, a general design has been used in widely varying environment conditions. Before making your purchase, get an assessment.

Gas Turbine Application: The quality of air inlet filters is essential for optimal gas turbine performance. Protecting the turbine with site-specific filtration solutions will assure profits are kept high.