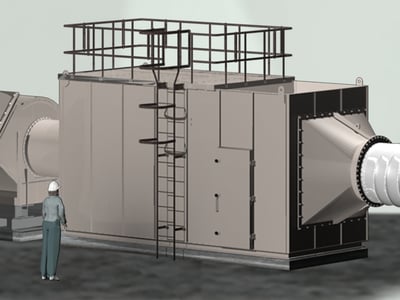

Diesel and gas engines need protection against the elements, excessive temperatures and contaminants during the combustion process. The surroundings also need protection from the hot exhaust gases. Robust solutions protect against any surge risk.

Dust particles from the ambient air will lead to the wear of internal combustion engines and its components such as pistons, rings, and cylinder linings, leading to costly maintenance repairs. These contaminants will also lead to a less efficient combustion process.

Using our robust and high-efficiency air inlet filter solutions will prolong your engine life, maintain its design performance, and reduce your CO2 emissions. This will ultimately lead to higher availability and increased profitability.

With test rigs that mimic extreme conditions, from salt and water spray to high air flows and high burst pressure, our R&D group focuses on ensuring reliability. We challenge our products in real site conditions using our mobile testing trailers, the CamLabs, and are always ready to show you actual performance data. Our patented solutions like the CamGT 3V-600 have pushed the industry limits when it comes to water handling capability, salt removal efficiency and lower operating pressure drop. When reliability is critical, your air filters should be just as dependable.

We strive to understand air and local conditions better than anyone else. A little obsessive? Maybe. But when up to 98% of what goes into your equipment is air, we believe it’s a good thing. By providing the facts you need to empower your decisions, you can optimize output and efficiency. As the most predictable air solutions provider, Camfil keeps your equipment working better and longer, while removing the element of surprise. We help you stay in control.

If you are designing a new system or simply looking to improve your current performance, ask us about our life cycle cost software, our air sampling solutions, or ask for a CamLab test.

Systems for anaerobic digesters and protection of biogas engines use adsorbents in leak-free housings for corrosion and abrasion control. Efficient, safe removal of hydrogen sulfide (H2S) and siloxanes helps you eliminate unscheduled repairs and downtime.

In dry, coarse dust environments, maintaining low pressure drop and long filter life are key to increasing availability. And when sites are challenged with fine particulates, salt or corrosive contaminants, final high efficiency filtration is recommended.

Camfil removes diesel emissions from outdoor air in IAQ applications. In process applications, we clean the exhaust stream close to the engine. The challenge is different; higher temperatures and higher contaminant concentrations.

Offshore installations must manage salt, water ingress and fine particulates from equipment exhaust. Multi-stage, built-in drainage and final hydrophobic high efficiency filtration that’s compact, robust and adapted to heavy water loads is recommended.

In rural and agricultural sites, engines require protection from seasonal contaminants and small particles. Fouling is caused by particles under 1 micron and even in apparently clean environments, high efficiency filtration is a must-have performance booster.

Colder climates bring the added challenges of heavy snow and frost to diesel and gas engines. Icing on filters can cause filter blockage, leading to high pressure drop.

Industrial and urban sites endure high levels of fine corrosive particulates from combustion, and chemical and industrial processes. High-efficiency multi-stage filtration that is compact and robust prevents engine fouling and maintains its optimal performance.

Coastal and tropical sites face the added risk of water ingress. Soluble particulate carry-over increases the risk of fouling and corrosion, especially if salt is present. Filtration should be robust and adapted to handle heavy water loads.

The newest pulse technology for the 21st century, TurboPulse takes a modern approach to filter design with many new features engineered to improve filter life and pulse performance for turbomachinery.

Energy and Power Systems

Not all people who purchase our products are experts in air filtration and they shouldn’t have to be either. The purpose of Camfil City is to give everyone a chance to learn the basics of what our clean air solutions can do for them.

Dust fume and mist extraction Take a Breath Food and beverage Air quality Virus Contamination Control Air cleaners and air purifiers Electronics and optics Life science and healthcare Commercial and public buildings Manufacturing and machinery Standard and regulations Education and experience Innovation technology and research Sustainability Case studies Energy and Power SystemsFor the first time, there is a GT-specific filter efficiency standard. Discover how ISO29461-1 can help you select the right filters for any turbomachinery application.