Electrical motor production has a high demand for clean air. Through many different contaminant generating activities, the motor production areas can often be the most polluted areas within this Industry. Removal of these often harmful contaminants is key to ensuring people, product, environmental and process safety.

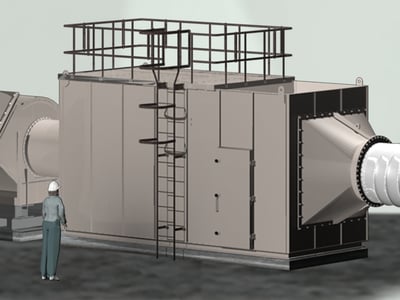

Dust collectors are most commonly used to capture harmful particles at the source in metalworking applications including welding, robotic welding, laser cutting, plasma cutting and thermal spray.

Laser cleaning and welding use hairpin production processes that generates dust, fume and VOC which are often hazardous to the health of operatives in the workplace and should be completely removed with a good exhaust air system.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

CamCarb XG Engineered for energy and maintenance cost savings in molecular contamination control applications

Food and beverage Electronics and optics Commercial and public buildings

Dust collection systems are all safety devices and thus state-of-the art modern methods of validation and certification are required. Furthermore it is vital to ensure that the system is still in compliance after perhaps changed process conditions, to provide maximum safety for personnel and the facility. It is also recommended to carry out quality audits, process reliability surveys and annual safety inspections.

Food and beverage Life science and healthcare Manufacturing and machineryOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.

When purchasing dust collection systems and filter cartridges, the initial purchase price is just the tip of the iceberg. The true costs – energy, consumables and operations – are lurking below the surface. The good news is that there are ways to reduce these costs over the long term.

HemiPleat is, in short, the uniquely, patented media pleating technology Camfil use to create highly efficient filter cartridges that outlast and outperform competitors alternatives.

Dust collection systems are an important part of any manufacturing process, so they need to be sized and designed properly. One critical design component is specifying the proper filtration media, which requires analysis of the dust in the process and all operating conditions.