Camfil’s robust molecular filters help to eliminate odour nuisances and remove heavily contaminated gases from this highly valuable resource for renewable energy, compost and soil enhancers.

When biodegradable organic waste is collected or segregated from a mixed waste stream, it provides value as a fuel for energy production or as raw material for compost or fertilizer. Important categories of organic waste include manure, food waste, grass cuttings and crop residues.

Anaerobic (without oxygen) digestion processes are used to make biogas, while compost is made using an aerobic (with oxygen) digestion process. Any biodegradation process produces a complex mixture of gases which can create an odour nuisance or, in the case of biogas, a corrosion hazard for the combustion engine. Molecular filtration helps to eliminate these problems.

Biogas is gaining importance worldwide as recycled organic waste replaces non-sustainable fossil fuel sources of energy production. When organic waste is digested in an anaerobic process, the resulting methane – the fuel for energy production – can be heavily contaminated with unwanted substances that can cause corrosion or abrasion.

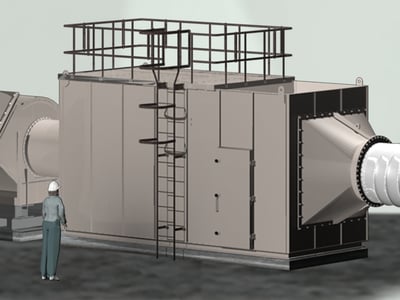

If high concentrations of H2S are allowed to reach the gas engine where the methane is combusted to generate energy, the engine can suffer internal corrosion due to a combination of the acidic gas and high temperatures. Engine corrosion requires unscheduled downtime for maintenance and repair – increasing maintenance costs and lowering output and profit for the biogas plant. Many anaerobic digesters and biogas engines are located close to the feedstock of organic waste, i.e. on farms. In-line molecular filtration is the accepted method of removing hydrogen sulphide from biogas prior to combustion.

Organic waste can be partially biodegraded in an aerobic process to make compost or soil-enhancing products. Little or no hydrogen sulphide is produced but a lot of the volatile organic content of the waste is released. This can create an odour nuisance due to the very high intensity. The gas mixture responsible for the odour is very complex, but a major constituent will be terpenes such as alpha-pinene.

You can use molecular filtration as an odour control method both on the exhaust from the production building and in the ventilation system of machinery used inside the process hall to turn and mix the rotting waste.

With Camfil’s dedicated molecular filtration solutions, you can keep troublesome odours away from neighbouring areas and filter out contaminated gases before they reach the combustion engine.

Protect the membranes that clean your biogas before injection. Control engine corrosion and abrasion with adsorbents in leak-free housings. Efficiently and safely remove hydrogen sulfide (H2S) and siloxanes to help eliminate unscheduled repairs and downtime.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

Did you know Camfil have a full range of retrofit filters that can be utilised in all the most common brands on the market. Camfil filters are not just designed to work but to optimise your dust extraction systems performance

Food and beverage Life science and healthcare Manufacturing and machinery Energy and Power Systems