Achieve hygienic air quality and reduce the potential for contamination in the dairy production process with complete air quality solutions from Camfil.

Protect your high-risk dairy process from impurities – and extend product shelf life – with pure, filtered air in your processing areas. Camfil’s energy-efficient filters, rigorously tested and certified to standards and designed for food applications, help manufacturers around the world reduce the risk of contamination and meet strict regulatory requirements.

Regardless of the type of dairy product, dairy processes involve receiving raw milk and then transforming it into finished products. Airborne impurities like yeast and mould fungi greatly impact the shelf life of dairy products like milk and milk powders, cheese, yoghurt, ice-cream and butter. Infant formulas are even more sensitive to process quality as the stake is infant life.

But eliminating airborne contaminants is no easy task because of their size – on average, about 0.6 microns. And even with clean processing equipment, its open vents or areas can allow microbe-filled impure air to come into contact with the products. Therefore, any process related components must comply with food safety as well as sustain cleaning procedures.

It’s no wonder, then, that dairy foods must meet stringent regulations and requirements for food production safety. Controlling air quality and air change rates, together with temperature and humidity levels, in cleanrooms and filling halls all play a key role in contamination control.

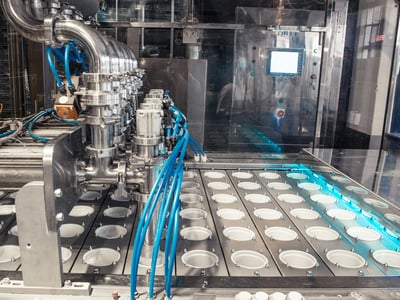

In this industry, you simply can’t skimp on quality. Fluid bed dryers, aseptic filling lines, slicing, maturing and packaging lines have got to be equipped with filters of the highest quality and most efficient filtration levels to ensure that food spoilage, recall and customer risk threats are completely removed.

What appears to be cost-saving equipment is risky. If that equipment has not been properly tested and certified to meet requirements, it could end up costing you much more in the long run.

Whatever the level of risk you face in a specific application or processing/packaging area, Camfil offers a huge variety of pre-filters, fine filters, HEPA filters, ULPA filters, terminal housings and recirculating air cleaners to meet your needs. Our ProSafe range makes the perfect choice for the process and change control demanded by the food and beverage industry. Fully compliant with all relevant industry standards, including ISO 846, EC10/2011, VDI 6022, EC 1935:2015, free of harmful components, and moisture resistance.

Dust collectors safely handle exhaust air from food processing and packaging applications, therefore improving the IAQ, preventing cross-contamination and reducing the nuisance dust in the workplace.

High air quality is crucial for product quality and safety in food and beverage production. Our AHU products are designed to protect your people, products and processes while also reducing energy costs.

In high-hygiene areas, products requiring the highest hygiene levels undergo final processing and packaging. Here, you need the highest air quality to effectively eliminate all contamination hazards. For dry dairy powder handling, aseptic filling, packaging and more.

In high-care areas, you need to protect equipment or minimise contamination before products enter a high-hygiene area. Here, you need high airflow and positive pressure environments. For ready-to-eat production, condensed dairy, cream, yogurt, frozen dessert processing and packaging, cheese processing, and drying halls.

Low-care areas include areas where production and product handling do not occur. Camfil recommends products that adhere to EN 16798 to best protect the health of your building occupants. For office spaces, main corridors, and reception areas.

Medium-care areas, where raw material is stored, need to be kept clean to protect against product contamination. These areas include milk receiving and storage, and raw ingredient handling.

Not all people who purchase our products are experts in air filtration and they shouldn’t have to be either. The purpose of Camfil City is to give everyone a chance to learn the basics of what our clean air solutions can do for them.

Air cleaners and air purifiers Food and beverage Life science and healthcare Sustainability Education and experience Innovation technology and research Virus Contamination Control Energy and Power Systems Air quality Commercial and public buildings Electronics and optics Standard and regulations Manufacturing and machinery Take a Breath Case studies

Case Study: Dual 9 air filter. Higher performance, extended life (3-4 times longer), lower total cost and increased containment collection.

Food and beverage Case studiesSome processes are more sensitive than others. If you work in the food and beverage or life science industries, you know how tough the demands on clean air are. To be sure you have the right filter, look for the ProSafe symbol.

The food and beverage industry is affected by unique air quality challenges that can risk the health and safety of workers, production equipment along with a potential for contamination. Let’s look at how high-efficiency air filters can provide an effective and affordable solution.

Dust is everywhere – in our homes, workplaces and the surrounding environment. One can be annoyed with the dust piled on the surface of the bookshelf but unfortunately there is a darker side; the dust can cause allergies, health problems and expensive issues in production processes and equipment.

GSX collectors are ideal for use in pharma, mining, food and chemical processing industries. They also provide a safer work environment in metalworking applications like welding and cutting.