Air filtration has a critical role in many power generation applications such as, wind, thermal, nuclear, or biogas. Air filters are critical for the safety and efficiency of the process.

In very competitive and regulated markets, innovative air filtration solutions can be a competitive advantage as it has a large impact on the profitability of operations. Understanding the local site conditions can optimize air inlet systems to meet your operation and maintenance needs, increase service internals, and output.

What are you looking for?

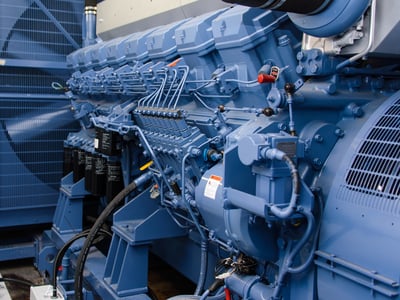

Diesel and gas engines need protection against the elements, excessive temperatures and contaminants during the combustion process. The surroundings also need protection from the hot exhaust gases. Robust solutions protect against any surge risk.

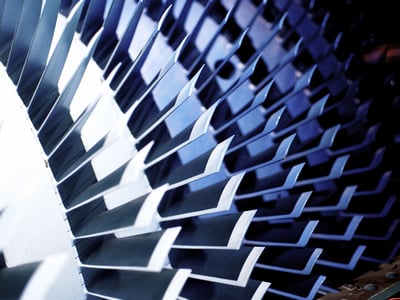

Gas turbines are highly efficient, sensitive machines that can be used to generate electricity or as a mechanical drive to power different processes. They are used all over the world in environmental and operational conditions that can vary drastically. That's why the filter solution should be adapted to offer adequate protection.

Turbomachinery and electrical equipment such as generators need protection against the elements and excessive temperatures with appropriate ventilation for cooling. The ventilation unit's level of protection should be customized based on its surrounding environment to protect against water, salt, and other contaminants.

Air compressors are critical for many processing industries that rely on efficient filtration to remain operational for prolonged periods of time, without any shutdowns. Environmental and operational conditions can vary drastically. That's why the required filter solution should be adapted to your local site conditions and operations.

Camfil has been providing solutions for nuclear power plants since the early 1960s. Today, we are the global leader in nuclear particulate and gas-phase filtration with experience from more than 90 plants around the world.

Wind turbines operate under some of the toughest conditions. Air inlet filters need to be highly efficient and robust to ensure a long service life and to minimise energy consumption.

A leading steel producer upgraded blower filtration, extending final filter life by 16x, pre-filter life by 4x, and achieving 100% operational availability.

Case studies Energy and Power SystemsGPSC Thailand upgraded the air filters on six of their gas turbines to TurboPulse T12 cartridge filters, achieving $520 000 USD savings annually, 166 000 MMBtu fuel reduction per year, 8 800 tons of CO2 reduction annually, and 3x improved compressor efficiency

Case studies Energy and Power SystemsThe newest pulse technology for the 21st century, TurboPulse takes a modern approach to filter design with many new features engineered to improve filter life and pulse performance for turbomachinery.

CCC Pesquería in Mexico upgraded to TurboPulse T10 filters, cutting power degradation by 5x, boosting annual output by ~20,000 MWh, adding $600,000+ in yearly profit, and lowering their carbon footprint.

Not all people who purchase our products are experts in air filtration and they shouldn’t have to be either. The purpose of Camfil City is to give everyone a chance to learn the basics of what our clean air solutions can do for them.

The wastewater undergoes a long process at Middelfart Wastewater, where the wastewater is treated and at the end of the process it eventually becomes purified water which is then released to the sea surrounding Middelfart. In addition, the byproducts biogas is converted to electricity and heat as well as bio-fertilizer that is being used on farmers’ fields.

Dyna Mig had a competitor dust collector solution that regularly caused costly downtime. With the help of Camfil’s expertise and a flagship Camfil Gold Series GSX dust collector system, Dyna Mig was able to eliminate all unscheduled downtime and cut their heating costs to a minimum – as well as work safer.

With a growing demand for greener practices, and rising operational costs, it has become imperative that gas turbine operators cut their carbon footprints. Upgraded air intake systems are one of the easiest, most cost-effective ways to meet these demands, while improving operations at the same time.

Protect your gas turbine from ice formation during high humidity and low temperatures. Insufficient icing protection may result in inlet filter system issues and ice formation at the turbine inlet.

A side by side comparison shows the benefits of higher grade GTC F9 gas turbine air intake filters for two RB211 gas turbines, even in very clean rural areas. It means a cleaner engine, higher power output, fewer water washes, and fuel savings.

Turbomachinery: Air inlet filtration systems should be designed to suit the environment. Because of market pressures, a general design has been used in widely varying environment conditions. Before making your purchase, get an assessment.

Case Study: In the gas turbine of a power plant in east China, Camfil China upgraded its pulse filter and retrofitted the prefilter from panel type to pocket type, new solution have been continuously running for more than 9500EOH, while original solution’s lifetime to pressure drop alarm value is less than 2000EOH.

Gas Turbine Application: Do you operate in a coastal or offshore site? Unfortunately, you probably have to deal with corrosion related issues. You can, however, operate corrosion-free if you take the right measures.

Learn more about how air filtration impacts turbomachinery performance, and what you can do to turboboost performance.

Hot corrosion is a source of nonrecoverable degradation on gas turbines. It is a chemical reaction between salts, sulfur and heat, where the damages can reduce an engine’s life by up to 75%. One of the most effective methods is to eliminate the contaminants triggering the chemical reaction. This paper examines the causes of hot corrosion and assesses various methods of mitigation.

Tata Power Ltd, India's largest integrated power company requests Camfil for a Cam-Flo pocket bag filter and CamGT static air filter retrofit after heavy hot corrosion in the gas turbine and high pressure drop jeopardized performance and safety.

Dalkia, a leader in the French gas turbine market, launched a national comparative test for various air intake filters, including Camfil's Hi-Flo pre-filters and CamGT EPA filters, to increase power production for their 10 GE LM6000 gas turbines.

If you are looking to expand your knowledge on the impact of air filtration on your gas turbines and other turbomachinery, look no more!

To answer this question, let's look at the difference between a land based gas turbine and a jet engine.

The biogas process is critical as it releases heavily contaminated gasses that can cause engine corrosion and equipment abrasion, causing unscheduled downtime for maintenance and repair, which results in loss of output and profit. Luckily, there are several ways of solving molecular filtration in biogas plants with different types of filter media in deep beds.

Case Study: The BioGas produced is heavily laden with H2S (hydrogen sulphide), a gas that can cause corrosion and pitting inside the gas engine. A solution was required where a high level of abatement of H2S was possible and an easy filter media maintenance.

Located offshore Ivory Coast, Africa, the CamGT EPA filter solution saves Foxtrot International 3 shutdowns per year and eliminates salt corrrosion, without compromising on footprint.

Activated carbon (also known as activated charcoal) is an exceptionally versatile material that can control the vast majority of molecules that pollute the air – that’s more than 150 million catalogued chemicals.

Egat North, the largest energy producer in Thailand, upgraded to Hi-Flo and CamClose air intake pre-filters as well as CamGT final EPA air filters and lowered degradation by 70%, reduced water wash requirements, and saved approximately $1.24M USD per year.

Learn how The Value Rating, the easiest way to select air filters for gas turbines, works.

Case Study: Clean Air For Cofely United Kingdom. Cofely, a GDF Suez company, is one of the leading experts in energy, technology and facilities management services with business outsourcing. Camfil provides City air purifiers to improve IAQ.

Hi-Flo bag air filters and CamGT EPA air filter upgrade reduces compressor efficiency degradation by 80%, slashes 3 offline filter replacements, 7 online pre-filter replacements, and 3 offline water washes per year.

The CamClose panel air filter is engineered for gas turbine air intake systems to provide hassle free operations, stable performance and increased protection.

Frequent pressure and short filter replacement intervals led to high operational costs. Camfil's Cam-Flo air intake pre-filters and CamGT EPA air filters met their goal of 8000 hours of life and reduced pressure drop by 50%.

An energy plant on the pacific coast upgrades their Siemens 501F gas turbine filtration to the CamGT 4V-300 air intake filters after tests show its water and salt handling capabilities.

Upgrade your gas turbine air inlet filters to cut carbon emissions per MWh produced.

Hinkley Point C in Somerset, United Kingdom is amongst the safest and most efficient nuclear power generator that is type of a Pressurised Water Reactor (PWR). With hundreds of megawatts electrical production in planning, safety of the process becomes a key concern.

Gas Turbine Application: The quality of air inlet filters is essential for optimal gas turbine performance. Protecting the turbine with site-specific filtration solutions will assure profits are kept high.

Camfil designs a static EPA retrofit gas turbine filtration solution for LM6000 turbines to ensure they deliver reliable power & heating to the district. The result of the upgrade was 3x more filter life, reduction in CO2 emissions by 1 100 tons per year, and fuel consumption savings of 650 000 Sm3 per year.

Noise complaints from neighboring communities in Thailand prompted the plants to evaluate a noise-reducing filtration system. The CamGT high efficiency air filter solution not only improved the noise levels, it also increased turbine availability, improved pressure drop and helped the gas turbine produce more power.

The Watson Cogeneration Plant operates 4 GE, Frame 7EA engines and produces 400 MW for local refineries and sells excess electricity to the grid. The Plant Manager requested air intake efficiency, pressure drop, and water tests from Camfil. The test results revealed the true impact of the synthetic cartridge filters on gas turbine performance.

CamPure 32 is the new ideal Camfil media for the removal of hydrogen sulfide during the production of biogas in an anaerobic process. Learn how this farm in France applied the high quality chemical absorbent media to their biogas application.

The CamGT air filter line has been turbo-boosted to maximize power, profits, and uptime of your gas turbine.

Air sampling, CamLab on-site analysis, as well as a Life Cycle Cost analysis show that the CamGT EPA filters will result in no shutdowns for turbine water washes, final filter shutdown extended to 5 years, decreased risk of corrosion and maximum power output.

Camfil Power Systems (PS) provides filtration and acoustical solutions for turbomachinery including gas turbines, generators,industrial air compressors and diesel engines. Turbomachinery technology has evolved tremendously over the past decades.

CamGT 3V-600 static final filters and Cam-Flo GT Hybrid pocket air filters eliminate 6 offline washes per year, improve gas turbine compressor efficiency, and boost power output for a Singaporean coastal cogeneration power plant.

Meeting stricter marine emissions standards while continuing to run reciprocating engines will significantly increase operating costs for commercial shipping operators. To support low emissions, liquified natural gas is becoming a key marine fuel due to increasing availability and clean combustion.