Metalworking facilities, especially those which perform large-scale fabrication, must be diligent in controlling harmful emissions in the workplace. Removing dusts, fumes and mist generated by various processes is a must for good housekeeping, worker safety, equipment reliability and regulatory compliance including environmental legislation.

The diversity of emissions in the metalworking industry is almost as big as the wide variety of applications. For one thing there are processes like welding, grinding or thermal cutting which generate dust and fume, on the other hand there are tooling machines which generate fine aerosols from the cooling lubricants. In both cases a system is required that captures, extracts and filters the emissions from the airstream before the cleaned air can be returned indoors or exhausted outdoors. As the type of extraction solution depends on the application, the processed materials and the properties of the emissions, it is crucial to fully understand the process.

Using an appropriate extraction system to control dust, fume and mist from metalworking processes makes a big difference in relation to the indoor air quality and thus for the protection of operators, processes and the environment. The following points should be considered in any risk assessment:

Health and Safety

Legislation typically requires that employers must ensure that adequate measures are in place for the Control of Substances Hazardous to Health (CoSHH) and that Workplace Exposure Limits (WEL) are not exceeded. Many emissions generated from metalworking applications can be harmful to operators health when getting airborne, especially when handling alloyed and stainless steel. The same is with as Metalworking Fluids (MWF) which are used in tooling machines for cooling the tools and cleaning the workpieces. Dust and mist deposits on the shop floor also can pose slip risks.

Combustion Risk and Dust Explosions

International standards such as the NFPA or the ATEX-directive have a few interpretations in different countries but it is typically a legal requirement and responsibility for an employer to carry out risk assessment and to understand if dusts that are generated or being handled as part of the process are combustible or potentially explosive and to what levels, specifically when processing light metals. This is to ensure safety of the operators, the production equipment and the entire facility in case of an explosion occurring. There is also a significant fire risk for some metal working processes.

Housekeeping

Uncontrolled emissions imply increased expenditure for housekeeping in the production and contamination from the processes can damage electrical controls, machinery or lead to malfunction.

High Energy Consumption

In general moving large air volumes and supplying compressed air is a costly factor when operating dust, fume and mist extraction systems. Besides that, the heat supply of large production areas poses massive energy consumption. Without recirculation of the cleaned process air or heat recovery there are additional costs for supply air or makeup air.

Manufacturers in the metalworking industry have to deal with a wide scope of applications and processed materials. As manifold as the process conditions are the solutions to extract and filter particles out of the air stream. Hereinafter some tips what to consider when determining the right extraction solutions for your application:

Dust Hazard Analysis:

Performing a dust hazard analysis is the best way to evaluate your facility’s risk for employee exposure.

Dust Explosion and Flammability Testing:

The ATEX-directive requires that the employer is responsible to carry out a risk assessment to determine the necessary fire and explosion protection.

Consider

Workplace Indoor Air Quality (IAQ):

To identify and control harmful

exposures to dust and fumes, you will need to conduct workplace

occupational hygiene assessment.

Identify Dust Characteristics:

It’s also important to analyse other dust

characteristics to determine the best dust collection system and

filters for your metal processing application.

Capture Solutions:

It is important to capture harmful dusts and fumes as close to the source as possible. In conjunction with the results from explosion & flammability testing, IAQ assessment and dust characteristic analysis, it is crucial to explore the right capturing solutions for your application (receiving hoods, enclosing hoods, capturing hoods or ambient extraction).

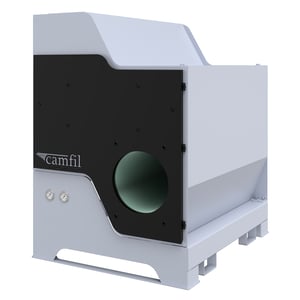

Filtration Technologies:

Depending on the application and the characteristics of the dust and fume, it is possible to do the job with a dry filtration systems or wet scrubbers. Whereas coolant mist from tooling machines is separated by emulsion and oil mist separators.

Explosion Protection:

If the dust is considered to be combustible or explosive, there are certain values that need to be determined so the correct NFPA or ATEX-certified explosion protection and explosion venting measures can be specified as part of the dust control system.

Energy Efficiency:

It is important that extraction systems are not only effective but also perform in an efficient manner in relation to energy consumption, compressed air usage, pressure drop and filter life time. The right system design is a key factor to assure the best possible performance of the extraction system and to reduce the operating costs.

Heat Recovery:

Recirculation of cleaned process exhaust air is possible when keeping below the local guidance for Workplace Exposure Limits of harmful emissions and may require a second stage HEPA filtration. Or alternatively the exhaust air can be diverted through a heat exchange and recovery system.

Harmful and combustible dust and fumes

For sticky or fibrous dust, wet dust, flammable or explosive dust

For metalworking fluids like emulsion, oil or MQL