Electrical motor production has a high demand for clean air. Through many different contaminant generating activities, the motor production areas can often be the most polluted areas within this Industry. Removal of these often harmful contaminants is key to ensuring people, product, environmental and process safety.

Protect the environment and people from dangerous or high concentrations of particles and molecules released by industrial processes, comply with local safety regulations and reduce operating costs of your exhaust air filtration system.

Laser cleaning and welding use hairpin production processes that generates dust, fumes and VOCs which are often hazardous to the health of operatives in the workplace and should be completely removed with a high quality exhaust air system.

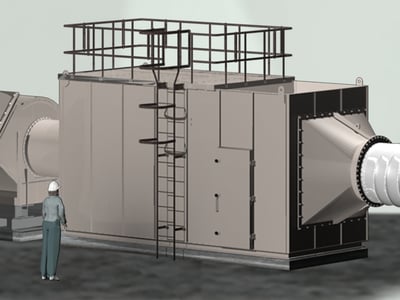

Dust collectors are most commonly used to capture harmful particles at the source in metalworking applications including welding, robotic welding, laser cutting, plasma cutting and thermal spray.

Energy Cost Index (ECI) 5-Star Rating System set the standards for air filter performance. The more stars means better air filter performance and higher energy savings. Get recognized for saving energy, shrinking waste, reducing carbon footprint and improving indoor air quality.

Air quality Virus Contamination Control Electronics and optics Education and experience Commercial and public buildings Manufacturing and machinery Sustainability Life science and healthcare Food and beverage Take a Breath Case studies

CamCarb XG - engineered for energy and maintenance cost savings in molecular contamination control applications

Electronics and optics Commercial and public buildings Food and beverageOften the initial purchase price for air filters or dust collectors is just the tip of the iceberg. The true costs for energy, maintenance and disposal are lurking below the surface. To make the most economic decision in the long-run, a detailed calculation considering all the factors will help to reduce your overall expenditure.